This blog is meant to be a resource to the LED sign industry, regardless of the display brand or provider. In this spirit, we’ll be going through some basic LED sign troubleshooting principles that apply to all LED signs. This can be helpful for those new to display ownership, having trouble identifying their display brand for support, or who just want to learn more about the technology.

If you haven’t done so already, check out part one of our LED Signs 101 series.

Identify the LED Sign Brand or Provider

Not all brands or providers have the same level of support. If it’s a Vantage LED display, we provide full support for the lifetime of the display and have one of the best warranty programs in the industry, so please reach out to us and we’ll get you taken care of asap. If you’re not sure what brand you have, look for labels on the front, side, or rear of the display. Most mainstream providers will label their product. If there is no label, you might be dealing with an OEM supplier, or direct over-seas drop ship display. These can be difficult to get support on, but the information below can help get you started on your own.

Basic Components for LED Signs

Although the quality and design approaches differ between manufacturers, there are general concepts that most outdoor LED signs will follow. This include basic operating components working together to create a full outdoor LED sign system. We talked about some of these in our earlier article, but some additional information applying to a wider range of LED brands is below.

Controller System:

This is the brain of the LED sign and usually the junction point for the communications, temp/light sensors, and video I/O for the entire sign. There are two main types:

PC Based Controller (IPC): These are typically internal industrialized computers running a full secure operating system. They are more powerful and tend to give more flexibility to the system for customization.

Embedded Controller: These will look more like a circuit board and are typically used in systems geared for static text and images. Many will play animations and some video, but the frame rate and storage space is limited.

Video Components and Modules

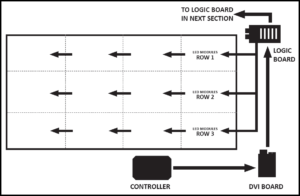

Video (DVI) Board: This converts the video signal from the controller into a readable format for the sign hardware. This board is sometimes combined with an embedded controller, but it usually separated on an IPC based system. Terminology can include: DVI Board and Sender Card.

Logic Board: These translate the video signal from the Video Board, to the individual LED modules on the sign, usually in rows or columns depending on the manufacturer. These are sometimes combined with embedded controllers on value systems. Terminology can include: Turbo Boards, Receiver Cards, Hub Cards, Row Boards, and Ribbon Boards.

LED Modules: These are the actual panels of LED’s that make up the entire sign. They can range is size depending on the pixel pitch (how close the pixels are to each other). The rear of the Modules will typically have the power and data connectors integrated. Terminology can include: Driver Boards, Tiles and LED Panels.

Power and Externals

Power Supplies: These power the internal hardware for the LED sign. They will usually take in AC voltage, and output DC voltage to the components. They will typically power more than one component or LED module.

Temperature Probe: These get outside temperature readings to display on the sign. They have been standard equipment on LED signs since the early days, but are used less frequently now as owners focus more on content and targeted advertising. They vary in appearance, from simple metal probes, to white “finned” units.

Communication Devices: Most signs use secured Wireless or Cell Modem communication devices these days, but many still use traditional wired solutions like Fiber Converters, and hardwired Cat5/6 Ethernet cable.

Accessing and Troubleshooting

Many of these components are located inside the display. There are multiple ways different brands provide access. The most common for general commercial signs is directly from the front by removing LED modules using a special key or tool provided by the manufacturer. Other options include rear doors if you have a large display with a catwalk. Some displays use hinged doors from the front. Once inside, the components are typically mounted to the back of the cabinet, or to the framework inside.

Follow the Data Chain

LED signs rely on a data chain to get data from one component to the next. Generally speaking, it looks something like this:

Common components and typical data flow. The configuration varies depending on the display brand, but the general concept is relatively standard.

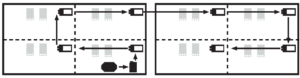

Typical data flow between the cabinets of the primary face (left) and the secondary face (right)

Keep it Simple

Look at your symptoms, and find a logical place to start ruling out causes of the issue. For example, if the sign has an LED module out, you wouldn’t start testing the communication devices. You would start looking at the LED sign hardware (LED Modules, Data cables, etc…).

Make the Issue Move

When physically troubleshooting components, try to make the issue move to a different location. This helps isolate the component to replace or repair. For example, move a blank LED module to a different part of the display, if the module remains blank the issue is likely the module itself. If it starts working, the issue might be something earlier in the data chain, like a data cable.

Re-boot

Electronic devices can lock up and require a reboot to get going again. Cycling power to the sign can sometimes fix issues. However, you shouldn’t have to do this constantly. If so, then look for the root cause of the freeze ups.

The Value of Technical Support

Display issues can seem complicated if your display provider doesn’t have support, documentation, or has gone out of business. Just remember to think linear, keep it simple, and take a step by step approach. You will find most issues can be isolated relatively quickly. Even the best LED signs will have issues now and then, but remember the quality of the provider’s design, warranty, components and support play a huge factor in how often this happens and how easy it is to fix when it does.

Stay Tuned for More

These principles will help build your foundation for troubleshooting LED displays, but stay tuned in for more! We’ll be going deeper into specific issues and how to solve them in future posts.

Link to our social media to be notified!